Electric racing isn’t just reshaping motorsport — it’s redefining the future of mobility. Welcome to Formula E, where the screech of tires is louder than the engines, and where every corner taken isn’t just about shaving seconds but sparking the next wave of innovation. Here, carbon fiber, silicon carbide, and sustainable composites dance with AI and algorithms. This isn’t racing as we’ve known it — it’s a lab on wheels, wrapped in speed and driven by volts.

From tire-burning city circuits to behind-the-scenes engineering marvels, let’s peel back the bodywork on the tech powering the latest generation of Formula E cars, and why it matters for both racetracks and the roads we drive on.

⚡ Power Like Never Before: The Hyper-Efficient Electric Drivetrain

If Formula 1 is the realm of horsepower, Formula E is the domain of pure efficiency.

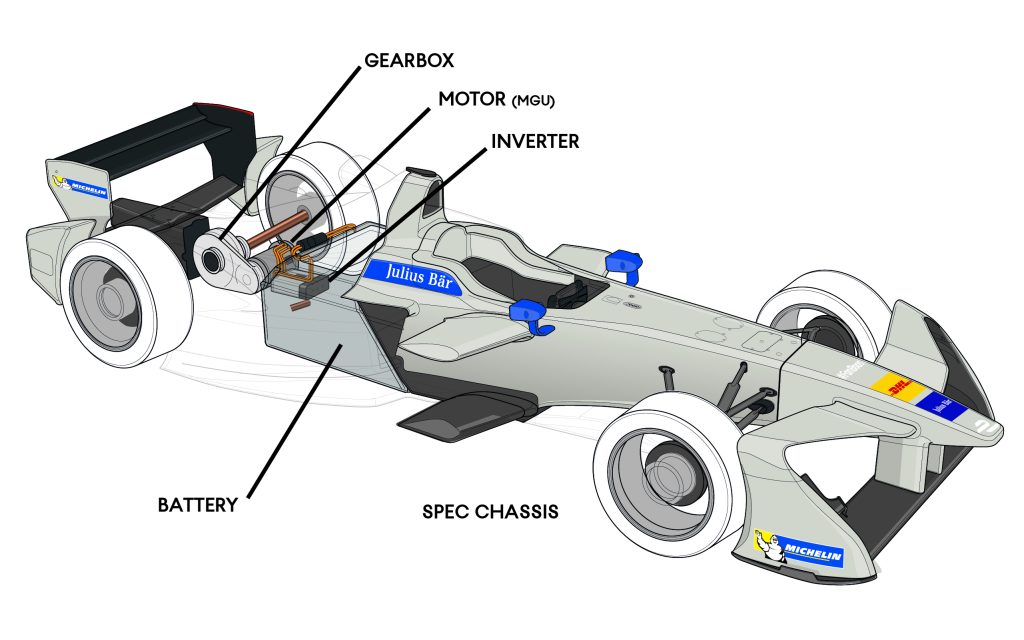

Today’s Formula E cars achieve electric motor efficiencies nearing 95%, a number that sounds fictional in the world of combustion engines. With no gearboxes in the traditional sense and instantaneous torque delivery, these cars leap out of corners like they’ve been yanked by magnets.

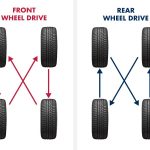

The Gen3 cars have introduced dual-motor systems — a rear-mounted 350 kW motor for propulsion and a front-mounted 250 kW unit solely for regenerative braking. That’s not just more power — it’s power with purpose.

There’s no clutch, no fuel system, and no turbo. Just electrons flowing with intent, delivering blistering acceleration with no delay. What you get is a vehicle that moves like a whispering bullet — swift, silent, and utterly surgical.

🔁 Regeneration 2.0: Braking That Charges You Forward

In traditional racing, braking is about slowing down. In Formula E, it’s about reclaiming power.

The Gen3 cars can recapture more than 40% of their total race energy through regenerative braking alone. Think about that — nearly half the energy they use on track is recovered on the fly.

This is made possible by a system that’s as complex as it is elegant:

- Brake-by-wire seamlessly blends regenerative and mechanical braking.

- The front motor acts as a massive generator, sending power back into the battery instead of using friction-based brakes.

- In some cases, the rear hydraulic brake system is hardly used at all.

Imagine hurtling toward a corner at over 250 km/h and slowing down without touching a brake pad. It’s as if the car’s own momentum is rewound, recycled, and relaunched back onto the track.

🧠 The Invisible Advantage: Software & AI Strategy

What makes Formula E uniquely futuristic isn’t just the electric motors — it’s the brains behind the brawn.

These cars are connected to a data matrix in real time. Teams run thousands of simulations before and during the race, using advanced telemetry, AI-powered predictive models, and high-speed data links to fine-tune every decision — from energy usage to tire life.

A driver lifts slightly earlier into a corner? The system adjusts the regen map. Battery temperatures rising? Torque output is shifted automatically. Software is the unsung hero — the hidden co-pilot working tirelessly to extract perfection from electrons.

This data-first philosophy is already bleeding into road EVs — energy optimization algorithms, smart regeneration systems, and thermal management tools all owe a thank-you to the black box brains born in the heat of competition.

⚙️ Silicon Carbide Inverters: The New Heart of Power Delivery

If the electric motor is the muscle, the inverter is the pulse.

In the newest generation of Formula E cars, traditional silicon has been cast aside in favor of silicon carbide (SiC) technology. These advanced semiconductors allow inverters to switch power faster, run cooler, and deliver energy with brutal efficiency.

The result? More compact systems, less heat waste, and more power delivered to the wheels where it matters most.

This tech isn’t just for the racecars. Manufacturers are already incorporating SiC inverters into production EVs — the same circuitry pushing cars to the podium is now helping push your EV farther on a single charge.

⚡ Pit Stop Power: Ultra-Fast Charging

In a world where charging time is the bottleneck for electric cars, Formula E is breaking down the door.

The Gen3 cars are built to accept up to 600 kW of charging power — six times faster than the average public EV charger. While still being phased into racing strategy, these capabilities open the door to game-changing moments:

Imagine a 30-second pit stop where your car gains enough energy for 10–15 laps. That’s not just a tactical shift — it’s an innovation with serious implications for consumer EV infrastructure.

What works under the pressure of a race weekend will eventually find its way to highways and parking lots across the world.

🌱 Racing Green: Sustainability Woven into Speed

Formula E doesn’t just talk sustainability — it builds it into the cars.

The Gen3 cars are the first formula racers to:

- Use recycled carbon fiber for their chassis and bodywork.

- Incorporate natural fiber composites like flax into aero parts.

- Feature recyclable battery components designed for second-life applications after their racing careers end.

Even tire compounds are changing, with manufacturers experimenting with renewable materials and sustainable rubber blends — all while meeting the brutal demands of competitive motorsport.

This philosophy of sustainable speed is already influencing road car production. It’s no longer about just going faster — it’s about doing it responsibly.

🧬 Aerodynamics and Lightweight Engineering for the Electric Era

Electric racecars play by a different set of rules than their combustion ancestors. Heavy batteries, high torque loads, and cooling demands mean engineers must rethink every inch of the vehicle.

Aerodynamics are finely tuned not just for downforce, but for battery cooling and drag reduction. The Gen3 car features:

- A clean, sculpted underbody to enhance airflow.

- Modular bodywork for easy replacement and recyclability.

- Minimalistic wings and splitters that prioritize efficiency over flash.

In short: less drag, more range, cooler batteries — and design lessons that translate directly to road-going EVs.

🔋 A Rolling Blueprint for Your Next Car

Formula E isn’t just racing — it’s engineering in fast-forward.

Whereas Formula 1 tech often takes years (or decades) to make it into consumer vehicles, the innovations from Formula E are already making their way into electric cars you can buy:

- Regenerative braking systems that adapt to your driving style

- Inverters using silicon carbide for better range

- Software-controlled brake blending

- Sustainable interior and exterior materials

- Real-time energy management systems

It’s no exaggeration to say that if you drive an EV in the next 5 years, some part of it — whether silicon, software, or sustainability — was born in the electric coliseums of Formula E.

🚀 Final Lap: The Future is Already Racing

We often think of the future as something far away — a place filled with possibilities yet to be realized. But Formula E is the future in motion. Right now, in city streets turned racetracks, the most advanced electric vehicles ever built are battling wheel-to-wheel, not just for trophies, but for technological supremacy.

And as they glide through hairpins and hammer down straights with near-silent fury, they’re carrying more than speed. They’re carrying lessons. Innovations. Blueprints.

Formula E isn’t asking if the electric future is ready. It’s answering the question in carbon, silicon, and silence.

The electric revolution isn’t coming — it’s already on pole position.